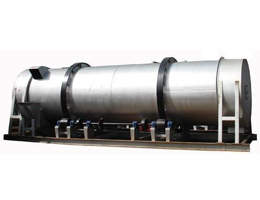

Sand Drier of double shell double pass type, specially designed to dry foundry sand, complete with Burner, motorised blower, drive unit for the Drier rotation, integral base frame and Special scoop feeding system is provided for charging the Drier from a lower height. The Shell assembly Tyres are supported on rollers mounted on a base frame. Two of the rollers are driven by a motor through a gearbox and chain drive. The shell assembly rotates by friction drive between the rollers and the tyres. The Panel consists of all the starters & Fuse units are provided inside a cabinet. A main switch, operating push button, actuators and indicating lamps are provided on the front face of the panel.

Core Shooter Machine is for the production of high quality cores. The machine is designed to produce the cores at high speed. Operation is by pneumatic or hydraulic supply and each auto operation is controlled by an Electrical Sequence Panel.

Rotary Polygonal Siever assures loosening and screening of foundry return sand. Solid parts and lumps are eliminated at the end of the screen.Large moulding sand lumps are largely disintegrated by the screening operation.

The complete screen is easily accessible. The mesh screen can easily be mounted or removed. The solid and simple construction assures low maintenance costs and long life. The closed construction and the protection of service doors assures safe operation. The proper functioning of the screen is monitored by rotational control.